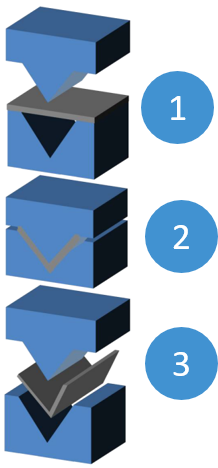

Hot Forming is a punch/die forming technique with a short cycle time using medium-high temperature to increase the formability of the material being formed.

This process results in a low thickness dispersion and involves punching a sheet, followed by forming at a controlled temperature (700°C for Ti-6Al-4V).

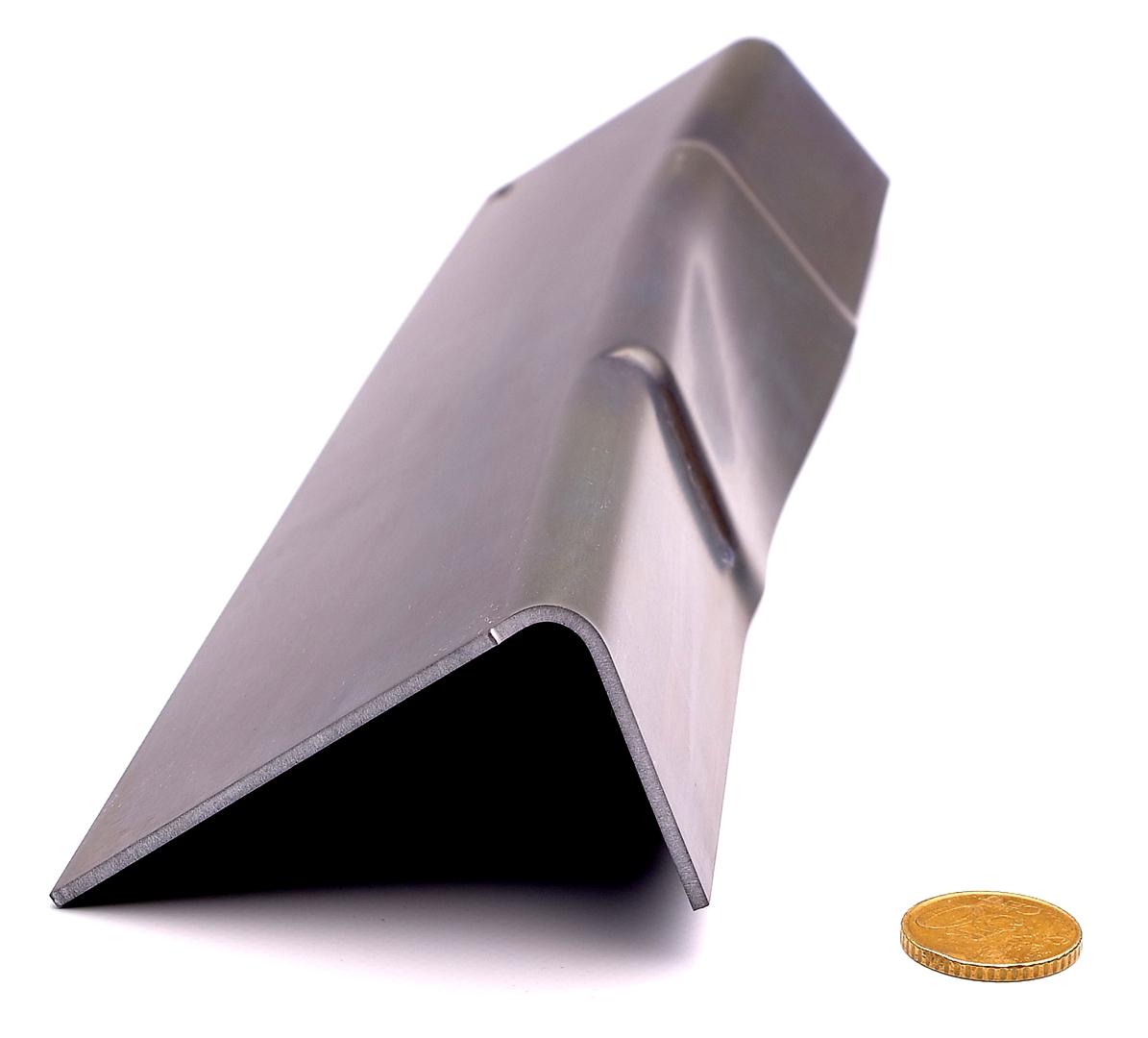

Hot forming is used for the production of deep drawing shapes and structures with high strength materials in a single cycle.

The parts typically produced with hot forming are:

- pylon panels

- nacelle panels

- piping components

- heat shields

- jet engine components

- compressor parts

Discover Cyril Bath Hot forming presses